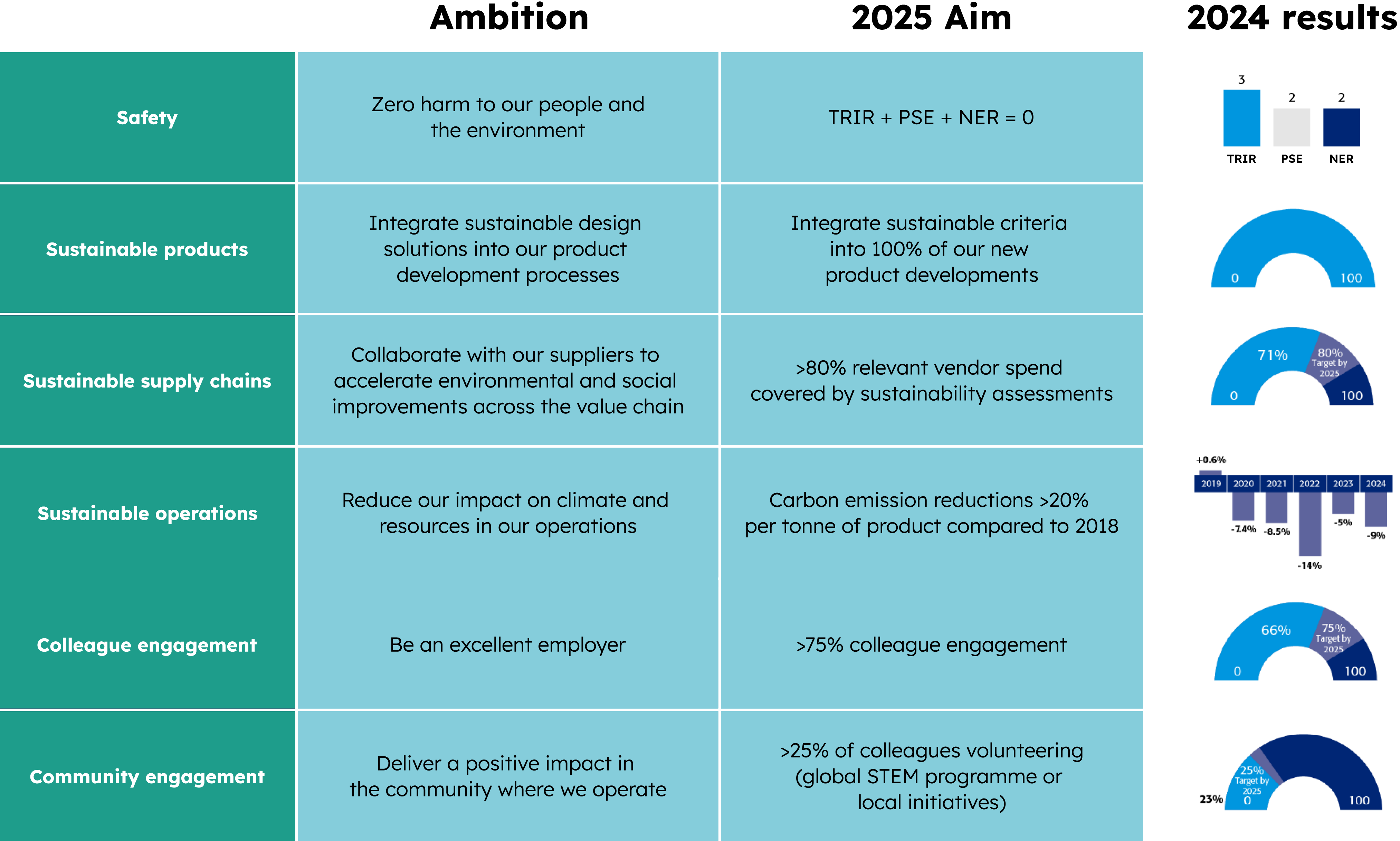

In 2024 we also refreshed our approach to managing our sustainability performance by introducing a new governance framework.

This strengthened governance framework has a clear escalation process giving senior leadership line of sight to our sustainability performance, initiatives and investments. Executive leaders will be directly involved in regular reviews to assess key strategic and operational areas through a sustainability lens.

Our corporate sustainability team will continue to act as a Centre of Expertise, guiding the different functions to help them achieve the ambitions in each area.

All our colleagues are encouraged to play their part in our sustainability journey and sustainability metrics are part of our incentive-based pay scheme.

The carbon intensity of our operations is factored into all colleagues’ annual bonus to further incentivise individual and collective action. An interactive dashboard gives all colleagues an overview of our carbon footprint and allows them to keep up-to-date with progress.